With plastic recycling rates varying widely depending on the industry and type of plastic in question, it can be difficult to find accurate information on just how much of the world’s plastic is actually recycled.

And that’s without considering efforts from oil companies and plastic manufacturers to greenwash their product by overstating its recyclable properties.

So, how much plastic really is recycled in 2024? Which plastics are best suited to recycling? And how do recycling rates vary around the world? Let’s find out…

Is plastic recyclable?

While most plastics are in theory recyclable, only a small percentage are recycled due to the complex nature of the process. Moreover, most plastic can only be recycled one or two times before degrading, limiting the practical benefits of plastic recycling.

Waste plastic must first be separated as different polymers like polyvinyl chloride (PVC), polypropylene (PP) and polyethylene (PE) cannot be recycled together. This first step is costly and time-consuming.

With composite plastics made up of multiple materials, it’s often not possible to separate the materials, with this category of plastics likely to end up in landfill or incinerated.

If the waste plastic can be separated, it is generally shredded and then melted down into a liquid state, ready for casting into a mould. This process alters the molecular structure of the plastic, thereby reducing the quality of the recycled product.

This is why plastic can only be recycled a few times before it becomes unusable. Chemical recycling, an alternative method, has been pushed by the plastic industry as a solution to this problem, but so far there is little evidence to suggest it can be implemented at scale.

The cost of plastic recycling and loss of quality associated with recycled plastic means that most manufacturers are still choosing to produce new plastics rather than recycle waste products, which are sent to landfill or incinerated instead.

Learn more about the great deception of plastic recycling below.

What plastic can be recycled?

While plastic recycling rates have improved, there are still some plastics that physically cannot be recycled and many others that are not recycled in practice due to the complexities of the process.

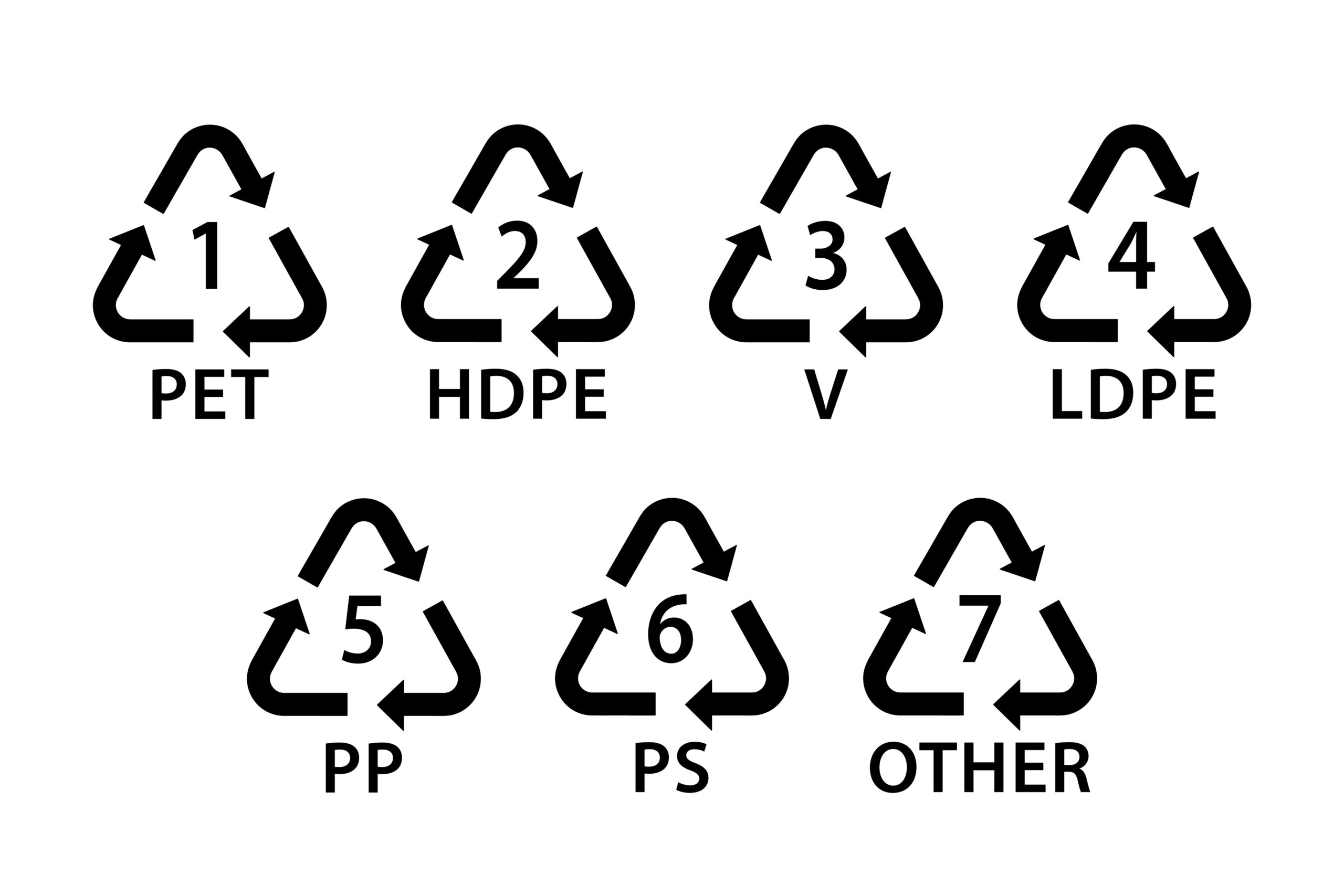

Resin identification codes have been introduced by many countries to indicate which plastic products can be recycled, though critics argue these are purposefully misleading and suggest all plastic can be recycled when the opposite is true.

The general rule is that the lower the resin identification number, the more likely it is that the product can be recycled – but even that doesn’t tell the full picture. Below, we take a closer look at recycling rates for the main plastics in the resin identification system.

PET

Polyethylene terephthalate (PET) is first on the resin identification system and is known as one of the more recyclable plastics. PET is commonly used to make drinks bottles, particularly for soft drink brands like Coca-Cola and Pepsi.

Despite its recyclable properties, PET recycling rates still fall short in many countries due to issues with collection. In the UK, it’s estimated that just 22% of PET is recycled, while the recycling rate for PET bottles in the USA in 2018 was 29.1%.

HDPE

High-density polyethylene (HDPE) sits second on the resin coding system and is again said to be recyclable. Everyday products made with HDPE include milk cartons, carrier bags, pipes and cosmetics bottles.

Recycling rates vary by product, with milk cartons having a strong circular economy but other products like carrier bags lagging further behind. Across the board, it’s estimated that recycling rates for HDPE in Europe are 10–15%.

PVC

Although only third on the resin identification list, PVC is not widely recycled due to the complexity of the process. Despite this, PVC is one of the most common types of plastics and is used widely in the packaging, construction and automotive industries.

One study into the PVC recycling rates across Europe between 2000 and 2020 found that just 3% of post-consumer PVC waste – accounting for 88% of all PVC waste – was recycled.

LDPE

Low-density polyethylene (LDPE) is used to make a range of products including cling film, sandwich bags, bin liners and disposable cups. It is the fourth resin on the identification system and has poor recycling rates.

Research from the US shows just 2% of HDPE waste was recycled across the country in 2019. Less data is available for the UK but as of 2017 only 17% of local authorities offered kerbside collection for plastic film, a product accounting for a large chunk of HDPE waste.

PP

PP is the fifth plastic on the resin identification coding system and like its predecessors can be recycled in theory but is rarely done so in practice. PP products are varied and include pallets, yoghurt pots, food storage containers and automotive parts.

According to the American Chemistry Council, less than 1% of post-consumer PP waste is recycled. Another study from the US found that plastic bottles made from PP had a recycling rate of 15.4% in 2020.

PS

Polystyrene (PS) is sixth on the list of resin codes. Widely used in the packaging industry for food and other consumer goods, PS is not commonly recycled due to its bulkiness and high contamination rates, both of which make the process challenging.

Information on PS recycling rates is limited but data from the US Environmental Protection Agency shows that just 3.6% of PS containers and packaging were recycled in 2018. Estimates for the UK put PS recycling rates at around 1-2%.

Other plastics

Beyond the plastics listed above, there are plenty of other materials that fall into the final bracket of the resin identification system. Many of these plastics are composites containing multiple materials, making them extremely difficult to recycle.

One example of a composite that has become increasingly popular in recent years is multi-layer composite pipe (MLCP), a material made with cross-linked polyethylene (PEX) and aluminium that manufacturers claim combines the best qualities of plastic and metal.

While MLCP often performs better than previous iterations of plastic pipe (namely PVC and PEX), difficulties in separating the different layers that make up the pipe mean that recycling is virtually impossible, marking a step back in terms of sustainability.

Not only that, but it can also take more than 450 years for MLCP to degrade, adding to the already excessive quantities of plastic waste sitting in landfill sites and leaching harmful toxins into the environment.

Learn more about the uses of different plastic polymers below.

How much plastic is recycled?

The most recent data puts the global recycling rate for plastic at 9%. In contrast, a huge 57% of plastic waste is sent to landfill, while 29% is incinerated and the remaining 6% is mismanaged.

Recycling uptake varies by country, with leaders such as China and India having rates of 13%. The likes of Canada and the USA, on the other hand, have considerably lower rates of plastic recycling at 6% and 4% respectively.

It’s also worth noting that recycling rates vary widely by industry. The packaging industry, for instance, has a relatively high recycling rate of 38% across the EU, while the construction sector, which relies more heavily on hard-to-recycle plastics like PVC and composites, recycles only a small fraction of plastic waste.

In recent years, recycling rates have slowed around the world and in some countries have dropped as production outpaces the adoption of recycling, which is yet to overcome the issue of diminishing returns associated with recycled plastics.

The move towards composite plastics like MLCP represents another major challenge, with these materials fundamentally at odds with the circular economy due to their inherent lack of recyclability.

New information has also come to light uncovering the plastic industry’s attempts to exaggerate the sustainability of plastic, prompting a shift in public opinion regarding its widespread use.

A landmark report recently published by the Center for Climate Integrity describes how the plastic industry misled the public about the potential of plastic recycling, knowing that it was “virtually hopeless” and would never be able to solve the plastic problem.

The lack of progress seen with plastic recycling rates seems to confirm these suspicions and in industries like construction with a record of using hard-to-recycle plastics there is now a growing demand for alternatives.

Clearly, the question is not how much plastic is recycled, or by what means can small gains be made to plastic recycling rates, but rather which materials with proven sustainability credentials can be used in place of plastics.

Learn more about greenwashing from the plastic industry below.

Plastic recycling: a great deception

With recycling rates for plastic waste stagnating, the practical deficiencies of plastic recycling have become harder to ignore. After decades of misinformation, it seems the main aim of plastic recycling has always been to justify the continued use of plastics rather than solve the problem of plastic pollution.

Attention must turn to phasing out plastics in favour of genuinely recyclable materials wherever this is possible, whether that’s with paper bags and glass bottles for packaging or metals in the construction industry.

Fed up with the plastics greenwash? Want to learn more about the role of copper in shaping a better future as a safe and sustainable alternative to plastic? Check out our other news items or subscribe to our newsletter.